While collecting materials on textile technology for this history-of-technology website, I naturally traced the sources back to Nong Shu ( 农书,The Book of Agriculture ) by Wang Zhen ( 王祯 ) of the Yuan dynasty. This work is not only a systematic survey of agriculture and handicraft technologies, but is also frequently cited in discussions of the history of Chinese movable-type printing.

To compare different printed editions, I consulted two versions available on Shuge, one of which is a Qing-dynasty Wuying Hall wood movable-type edition ( 清武英殿木活字版 ). It was this edition that led me to a very concrete realization:

This conclusion is not based on theory or historiography, but on direct examination of the printed pages themselves.

1. What the Pages Reveal: Visible Defects of Wood Movable Type

In the Wuying Hall wood movable-type edition, even a casual inspection reveals striking issues.

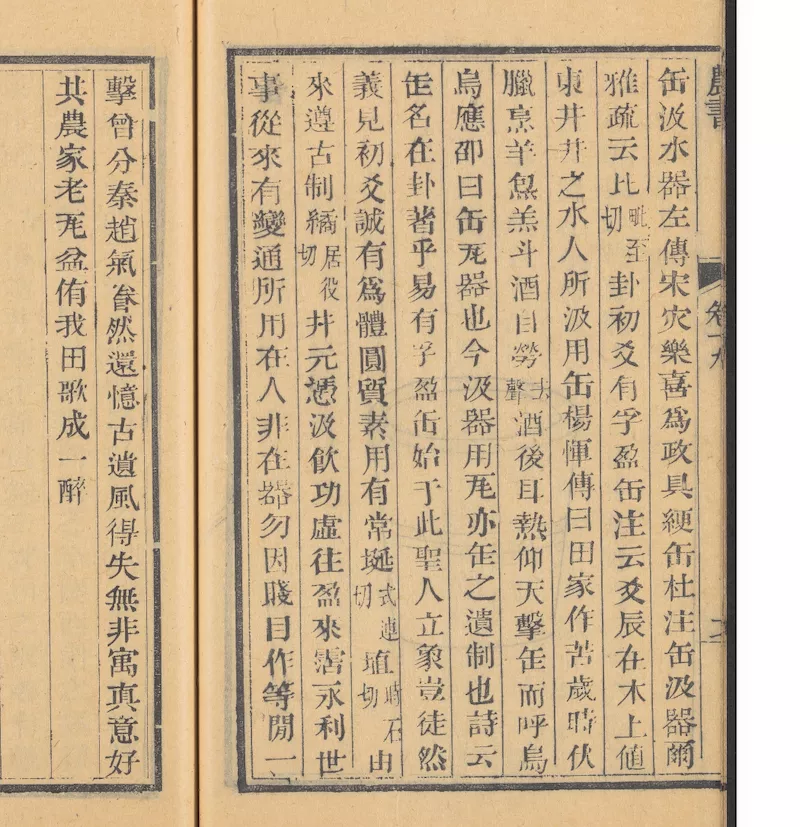

1. Uneven and unstable text alignment (Figure 1)

Across a single page, one can clearly observe:

- Characters that do not share the same vertical axis

- Some glyphs leaning slightly left, others slightly right

- Lines that appear straight at a glance but collapse under closer inspection

This does not look like sloppy workmanship or poor proofreading. Instead, it resembles a systemic instability inherent in the printing method.

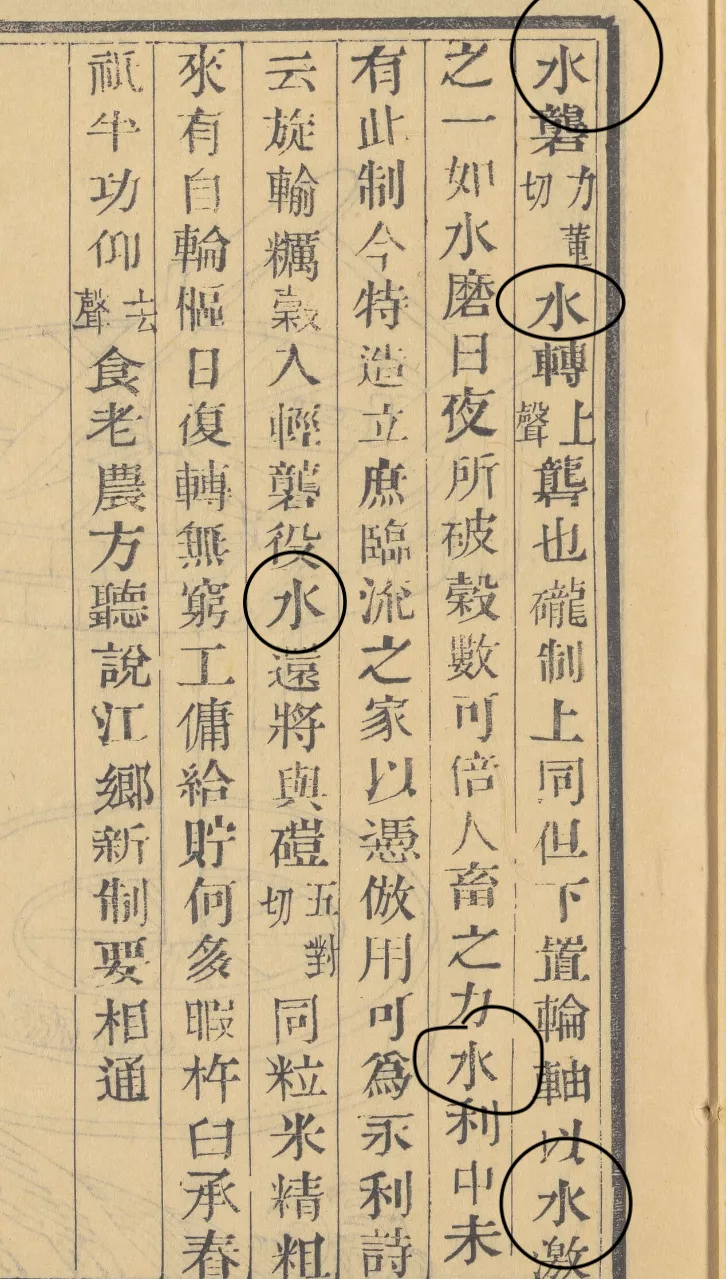

2. The same character appears in different forms (Figure 2)

More critically, within a single article:

- The same character (for example, “水”, water)

- Appears repeatedly

- Yet shows noticeably different shapes, proportions, and visual weight

At this point, the issue is no longer aesthetic. It is a technological problem.

2. The Root Cause: Wood Movable Type Is “One-Off, One-Character Production”

The problem with wood movable type does not lie in a lack of craftsmanship, but in its fundamental production logic.

The essence of wood movable type is this:

- Each character

- Is carved individually

- As a non-replicable handcrafted object

Under these conditions, several outcomes are inevitable:

- Character uniformity is impossible

- Even with the same artisan, it is extremely difficult to ensure:

- Identical stroke thickness

- Identical proportions

- Identical visual center of gravity

- Assembly errors cannot be eliminated

- During typesetting:

- Each character introduces its own angular and positional deviation

- A line of twenty or thirty characters accumulates error

- A full page inevitably develops a visible sense of distortion

These are not operational mistakes. They are structural defects.

3. Why Metal Movable Type Is Fundamentally Different

If we switch to cast metal movable type, the situation changes qualitatively.

Metal movable type introduces not just a new material, but a new mechanism:

- The same character can be cast repeatedly from a single mold

- Dimensions, height, and center of gravity remain consistent

- Geometric error during typesetting is dramatically reduced

This means that:

In a typical text:

- Characters such as “之”, “其”, “水”, “人”

- May appear hundreds of times

If these characters are produced from the same mold, both print quality and layout stability improve by an order of magnitude.

Wood movable type offers none of these benefits.

4. Why Wood Movable Type Is Often Worse Than Woodblock Printing

This also explains a long-ignored historical reality:

The reason is straightforward.

The advantages of woodblock printing:

- An entire page is carved as a single geometric unit

- Spatial relationships between characters are fixed at carving time

- Proofreading is done once, globally

- Printing introduces almost no assembly error

By contrast, wood movable type requires:

- Carving large numbers of individual characters

- Sorting, storing, and retrieving them

- Reassembling them into pages

- All while tolerating cumulative assembly errors

Under these conditions:

This is not a matter of cultural preference. It is an engineering decision.

5. An Uncomfortable but Technically Accurate Conclusion

Based on the actual performance of the Nong Shu wood movable-type edition, a clear conclusion emerges:

It possessed neither:

- The structural stability of woodblock printing

- Nor:

- The scalability and repeatability of metal movable type

As a result, it occupied an awkward middle ground and failed to become a dominant technology.

Conclusion: Where the Real Divide in Printing Technology Lies

This encounter with the wood movable-type Nong Shu reinforces a broader lesson in the history of technology:

Wood movable type did exist.

But under real production constraints and engineering realities,

it struggled to outperform woodblock printing and could not naturally evolve into an efficient, scalable system.

And that, perhaps, is a far more meaningful question than simply asking who invented what first.

MECHANICA PLANET

MECHANICA PLANET

COMMENTS (1)

Please Login to join the discussion.

good