Few technologies have shaped human civilization as profoundly as textile production. For thousands of years, clothing, sails, ropes, and fabrics defined economies and daily life—and the quest to produce them more efficiently altered the trajectory of global history. The shift from handcraft to mechanized textile machines became the spark that ignited the Industrial Revolution.

This article traces that remarkable journey—from ancient hand spindles to today’s AI-assisted automated textile systems.

1. The Origins: Early Textile Production (Prehistoric – 1500s)

1.1 Hand Spinning: The First Step

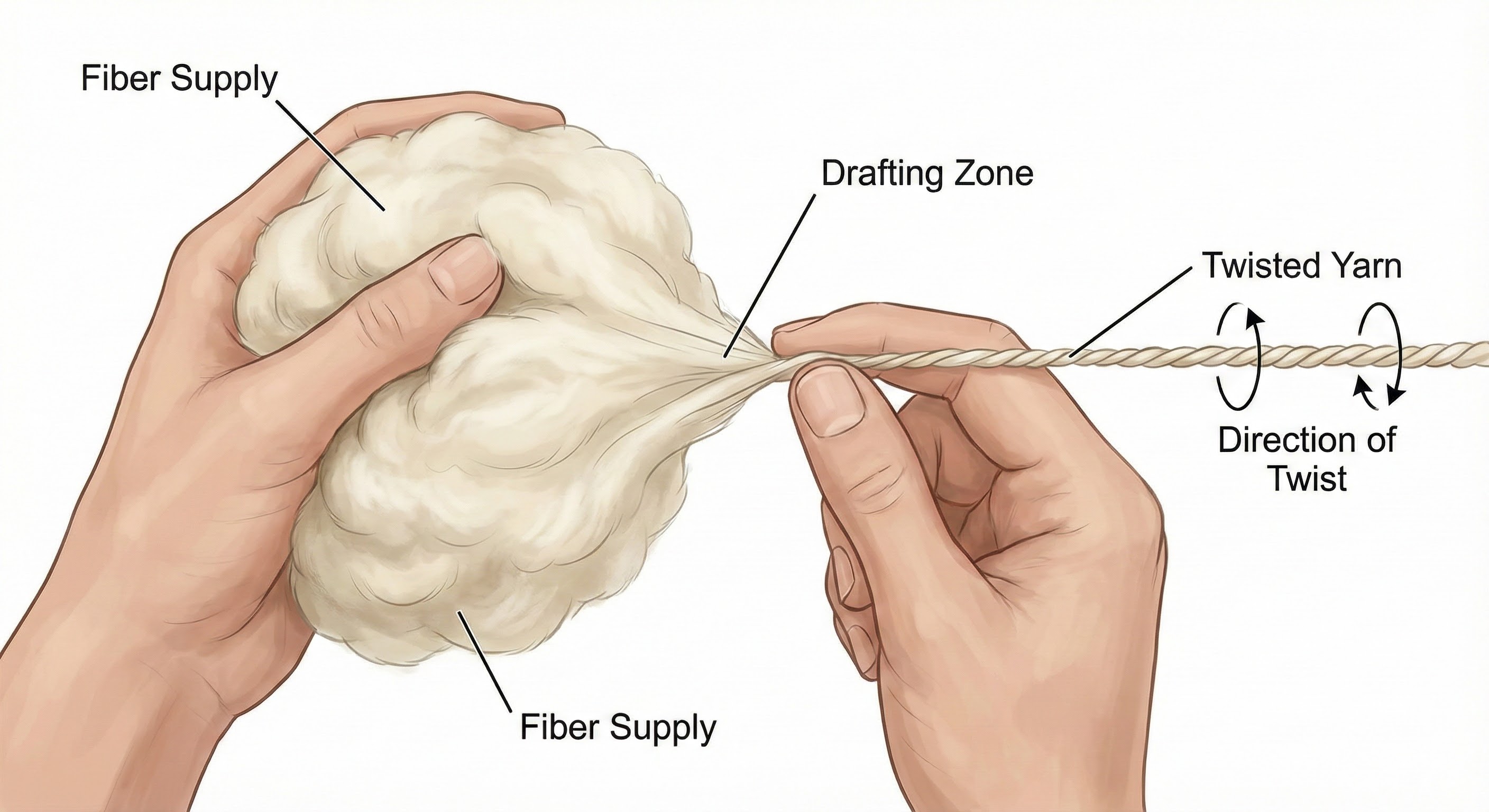

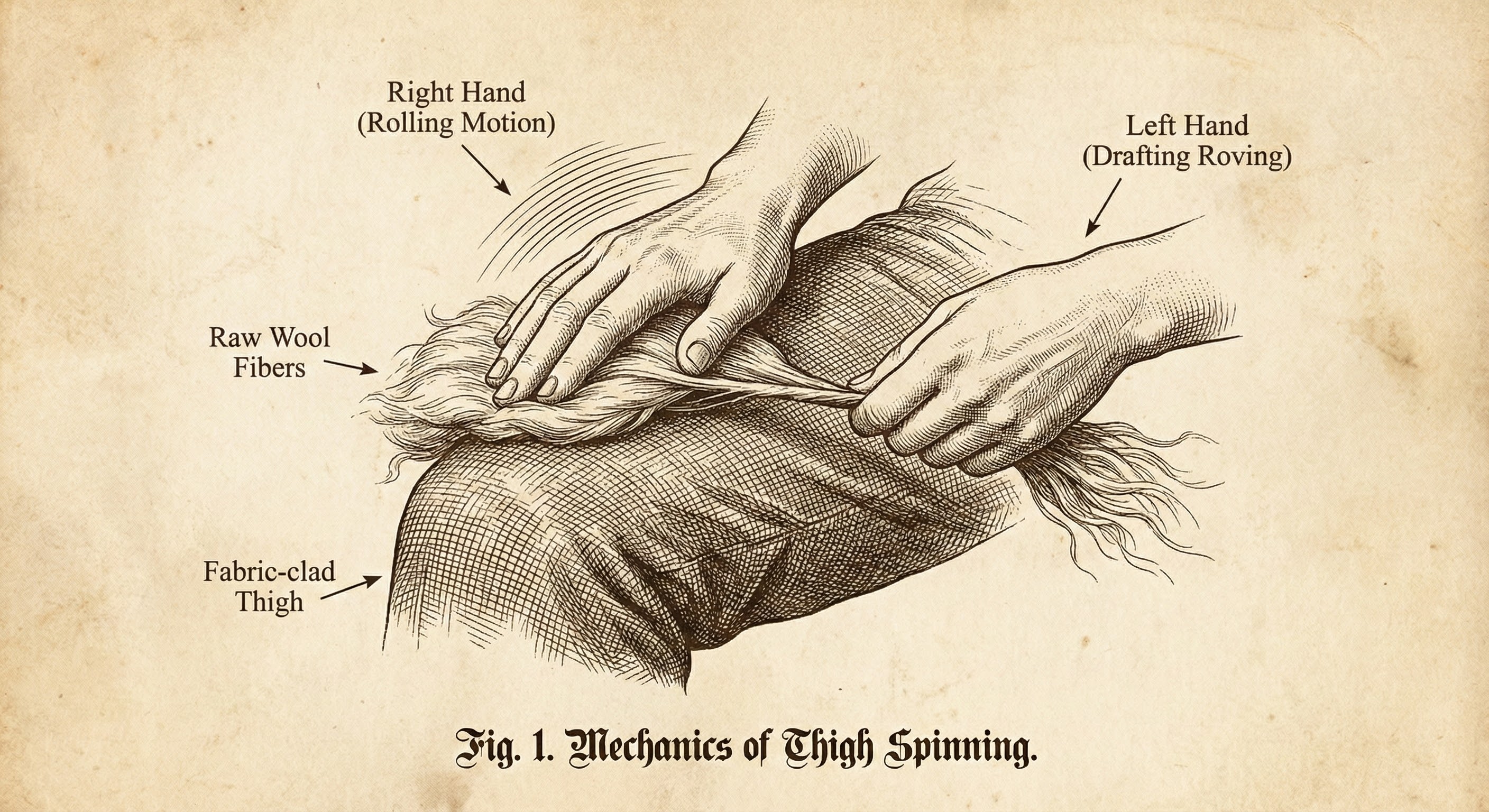

The earliest textile production dates back to the Neolithic era. People twisted fibers—wool, flax, cotton—by hand to create yarn.

Finger Twisting

Thigh Spinning

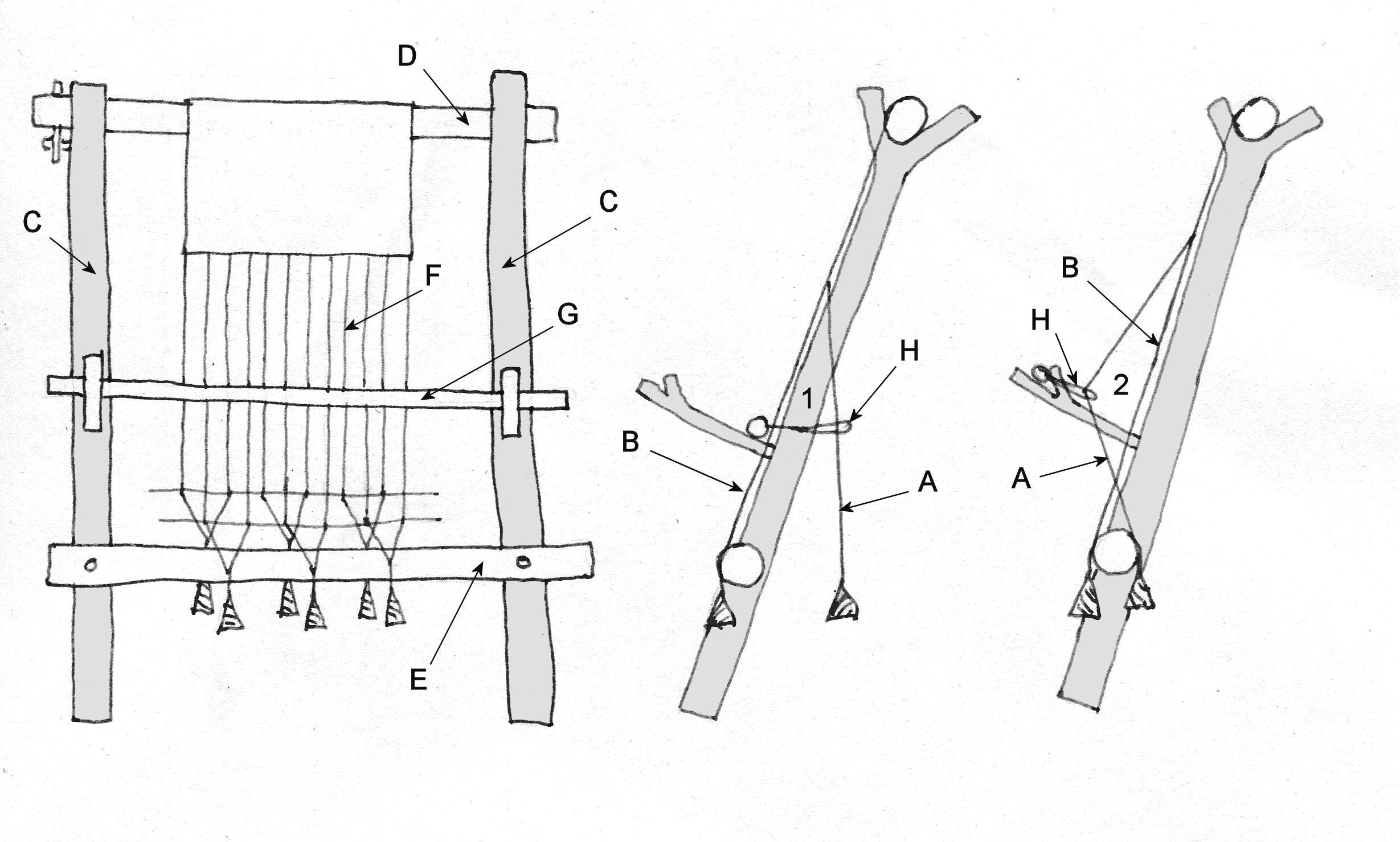

Over time, they invented tools:

Drop spindle (c. 5000 BCE)

Warp-weighted looms in ancient Greece and Europe

These tools were ingenious for their time but demanded enormous manual labor. One weaver could consume the output of several full-time spinners. This imbalance remained a fundamental constraint on textile production for millennia.

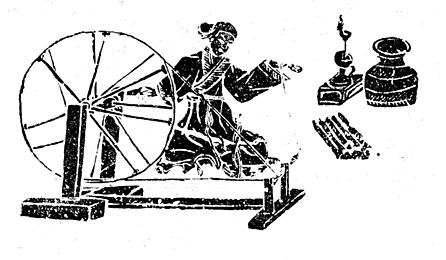

1.2 The Spinning Wheel (c. 1000 CE)

Originating in India or China, the spinning wheel spread across Eurasia. It allowed continuous spinning by turning a wheel instead of twisting fibers manually. Productivity increased several-fold—but the fundamental bottleneck remained: spinning was still too slow for the growing demand of global trade.

By the 16th–17th centuries, Europe’s demand for textiles (wool, linen, cotton) exploded—but production methods stayed medieval. Something had to change.

2. The First Breakthrough: The Flying Shuttle (1733)

In 1733, English inventor John Kay created the flying shuttle, which allowed a single weaver to operate a much wider loom and pass the shuttle at high speed using pulling cords.

Impact:

- Weaving sped up dramatically.

- Fabric widths increased.

- Demand for thread skyrocketed—exposing the spinning bottleneck like never before.

The flying shuttle didn’t mechanize weaving entirely, but it created intense pressure that triggered the search for automated spinning.

3. The Age of Spinning Machines (1760s–1780s)

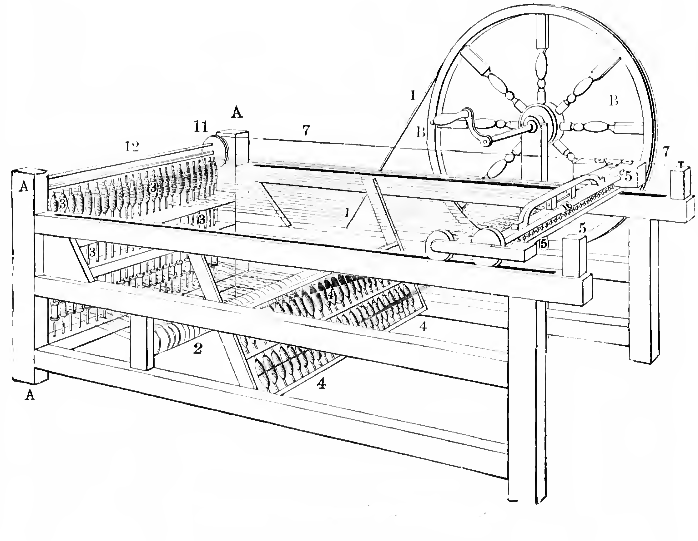

3.1 Spinning Jenny (1764) – Hargreaves

James Hargreaves’ Spinning Jenny allowed multiple spindles to be operated simultaneously.

Early models spun 8 spools; later ones over 120.

Strengths:

- Huge boost to productivity.

- Easy to operate in cottage homes.

Weaknesses:

- Produced weaker thread.

- Still relied on human power.

It was a transition technology—pointing toward industrial-scale spinning.

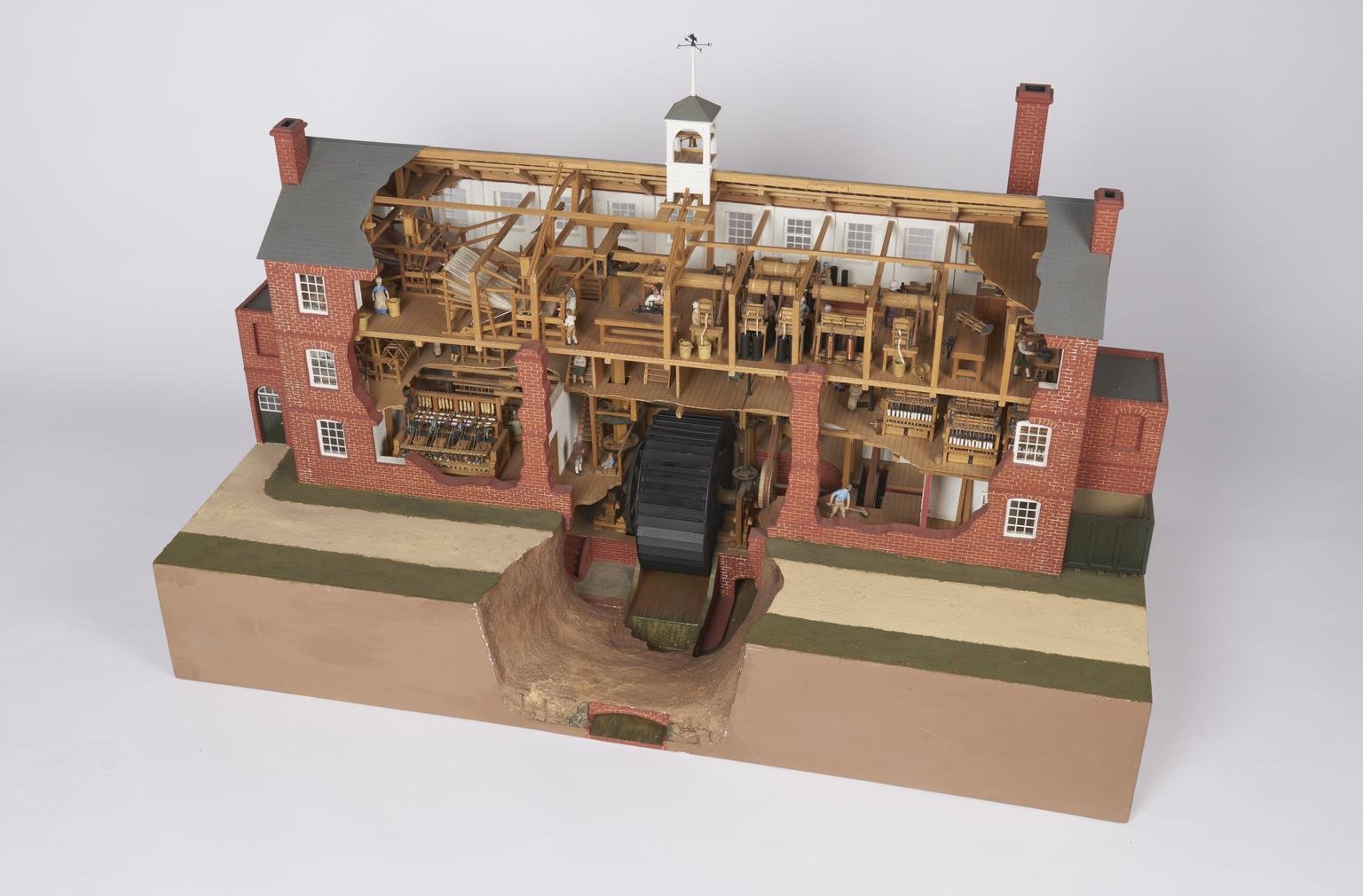

3.2 Water Frame (1769) – Arkwright: The First Industrial Machine

Richard Arkwright’s Water Frame used water wheels to power spinning rollers that produced strong, uniform thread.

Why it was revolutionary:

- Required large, rigid, multi-story buildings → the world’s first factories.

- Produced strong warp yarn (ideal for weaving).

- Organized labor shifted from homes to centralized mills.

Arkwright’s system marks the true beginning of the factory age.

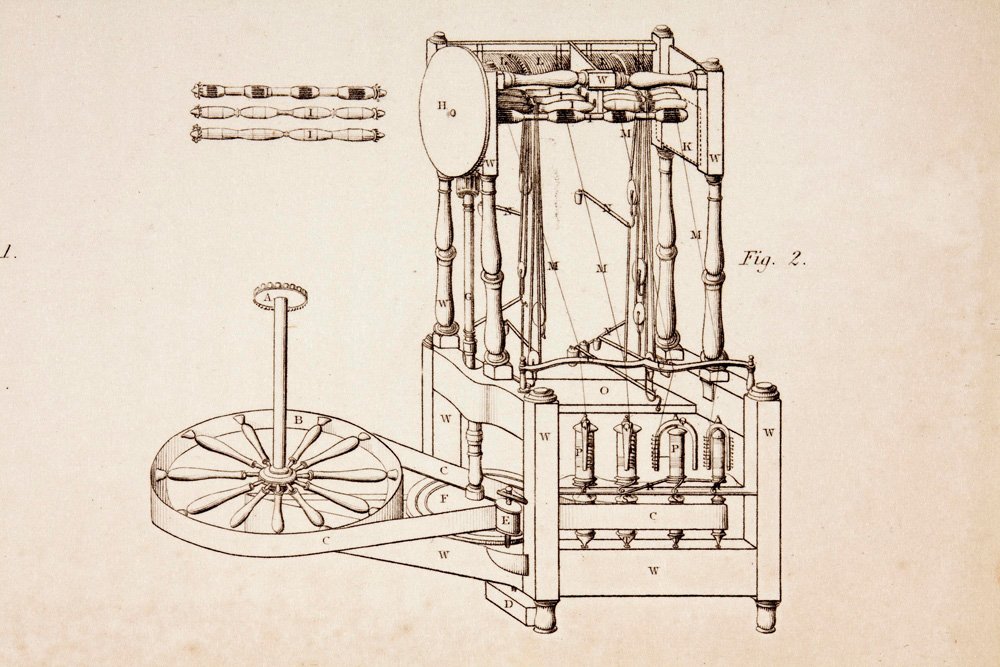

3.3 Spinning Mule (1779) – Crompton

Samuel Crompton combined the Jenny’s flexibility with the Water Frame’s power, creating the Spinning Mule. It produced high-quality yarn suitable for every kind of textile.

By the early 1800s:

- A single mule could operate hundreds of spindles.

- Mills installed thousands of spindles per building.

- The price of cotton yarn dropped over 90%.

This turned spinning from a slow cottage craft into a massive industrial enterprise.

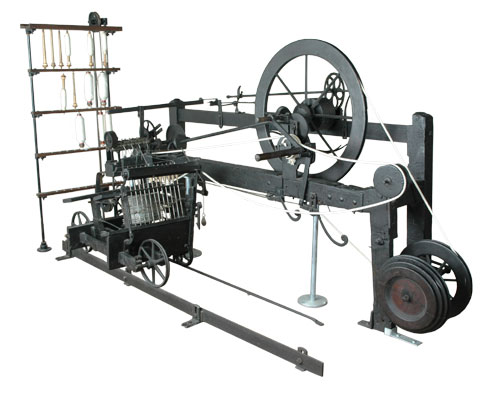

4. Mechanizing Weaving: The Power Loom (1785–1830s)

4.1 Cartwright’s Power Loom

In 1785, Edmund Cartwright patented a loom powered not by human hands but by mechanized motion. Early versions malfunctioned often, but by the 1810s–1830s, engineers refined the design.

4.2 Adoption and Impact

By 1850 Britain had:

- 250,000+ power looms

- tens of thousands of factory workers, many women and children

- Entire cities built around textile mills (Manchester, Leeds, Bradford)

Mechanized weaving completed the transformation begun by the spinning machines.

5. The Cotton Gin (1793): Solving the Raw Material Bottleneck

Eli Whitney’s cotton gin separated cotton fibers from seeds 50× faster than manual labor. This made cotton extremely cheap and abundant.

Global consequences:

- British mills demanded more raw cotton.

- The American South expanded cotton plantations.

- Tragically, this increased the demand for enslaved labor.

Technology solved one problem while deepening another—showing that machines don’t exist in a vacuum.

6. Steam Power and the Rise of the Mill System

Around 1780–1820, the adoption of Watt steam engines revolutionized textile factories.

What steam power enabled:

- Mills no longer needed rivers.

- Urban factories grew in major cities.

- Production ran day and night.

- One engine powered hundreds of machines via line shafts and belts.

Cities like Manchester became the world’s first industrial megacenters.

7. The Jacquard Loom (1804): A Digital Precursor

Joseph Marie Jacquard invented a loom that used punched cards to control patterns automatically.

Why it matters:

- Produced intricate textile designs without skilled weavers.

- Introduced programmability to machines.

- Inspired early computer pioneers (Charles Babbage, Herman Hollerith).

In a real sense, the Jacquard loom was the first machine to use software.

8. Global Expansion and the 19th Century Boom

By the mid-19th century, mechanized textile technology spread across:

- Britain (global leader)

- United States (Lowell mills)

- France & Germany

- Japan, after Meiji reforms

This led to:

- Mass-produced clothing

- Falling prices for everyday fabrics

- Rapid growth of export-driven economies

- Formation of modern labor movements (including Luddite protests)

Textiles were the prototype industry for all later industrialization.

9. The 20th Century: Electrification and Automation

9.1 Electric Motors

Individual electric motors replaced line shafts, making factories:

- safer

- more flexible

- more energy-efficient

Machines could stop independently, improving worker safety and control.

9.2 Shuttleless Looms

Mid-20th-century innovation introduced:

- rapier looms

- air-jet and water-jet looms

- projectile looms

These were vastly faster, quieter, and more precise.

9.3 Synthetic Fibers

Nylon, polyester, and acrylic required new spinning and weaving technologies, transforming global fashion and industrial textiles.

10. The Late 20th – 21st Century: Digital, Robotic, and AI-Driven Textiles

Modern factories now use:

- Computer-controlled Jacquard systems

- Robotic material handling

- AI-based defect detection

- Fully automated spinning frames

- IoT monitoring for temperature, humidity, and machine health

- Digital weaving with micron-level precision

China, India, Bangladesh, and Vietnam have become global manufacturing hubs.

The textile machine has evolved from a wooden frame in a cottage to a fully automated robotic system monitored by software.

11. Why the Textile Machine Changed Everything

Textile mechanization did more than create cheap cloth. It triggered cascading transformations:

Economic

- Sparked the Industrial Revolution

- Created the first large-scale factories

- Lowered costs, creating mass consumer goods

Social

- Drove urbanization

- Reshaped labor from skilled artisans to factory workers

- Inspired early labor rights movements

Technological

- Introduced programmability (Jacquard → computers)

- Provided engineering patterns for all later automated machinery

Global

- Built worldwide supply chains

- Shifted the balance of geopolitical power

- Influenced patterns of colonization and industrial competition

In essence, textile machines wove the blueprint of the modern economy.

Conclusion: From Hand Spindle to Hyper-Automation

The journey of textile machinery reflects humanity’s broader technological story: a relentless push for efficiency, scalability, and automation. Beginning with a simple spindle, evolving through steam-powered mills, and now reaching AI-driven factories, this evolution shows how a basic need—clothing—became the engine of global industrial development.

As we step into an era of smart factories and sustainable materials, textile machinery continues to evolve, reminding us that even the most ancient industries can remain at the forefront of innovation.

MECHANICA PLANET

MECHANICA PLANET

COMMENTS (0)

Please Login to join the discussion.