The spinning wheel is one of the most important inventions in the history of textile production. It transformed spinning from an intermittent, hand-powered action into a continuous, mechanically assisted process, dramatically increasing productivity. For centuries before industrial factories, the spinning wheel was the backbone of household and workshop textile economies across Eurasia.

A spinning wheel is a mechanical device that converts continuous rotary motion into twist in fibers, allowing yarn to be produced faster, longer, and more evenly than with a drop spindle.

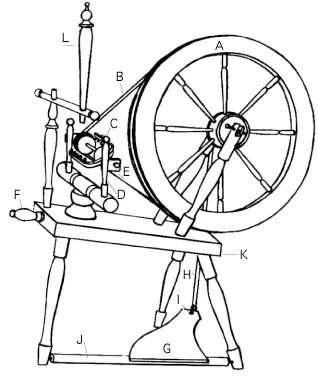

Core components include:

Once set in motion, the wheel provides steady, uninterrupted rotation, freeing the spinner’s hands to focus on drafting fibers.

This separation of twist generation and fiber control is the wheel’s key advantage.

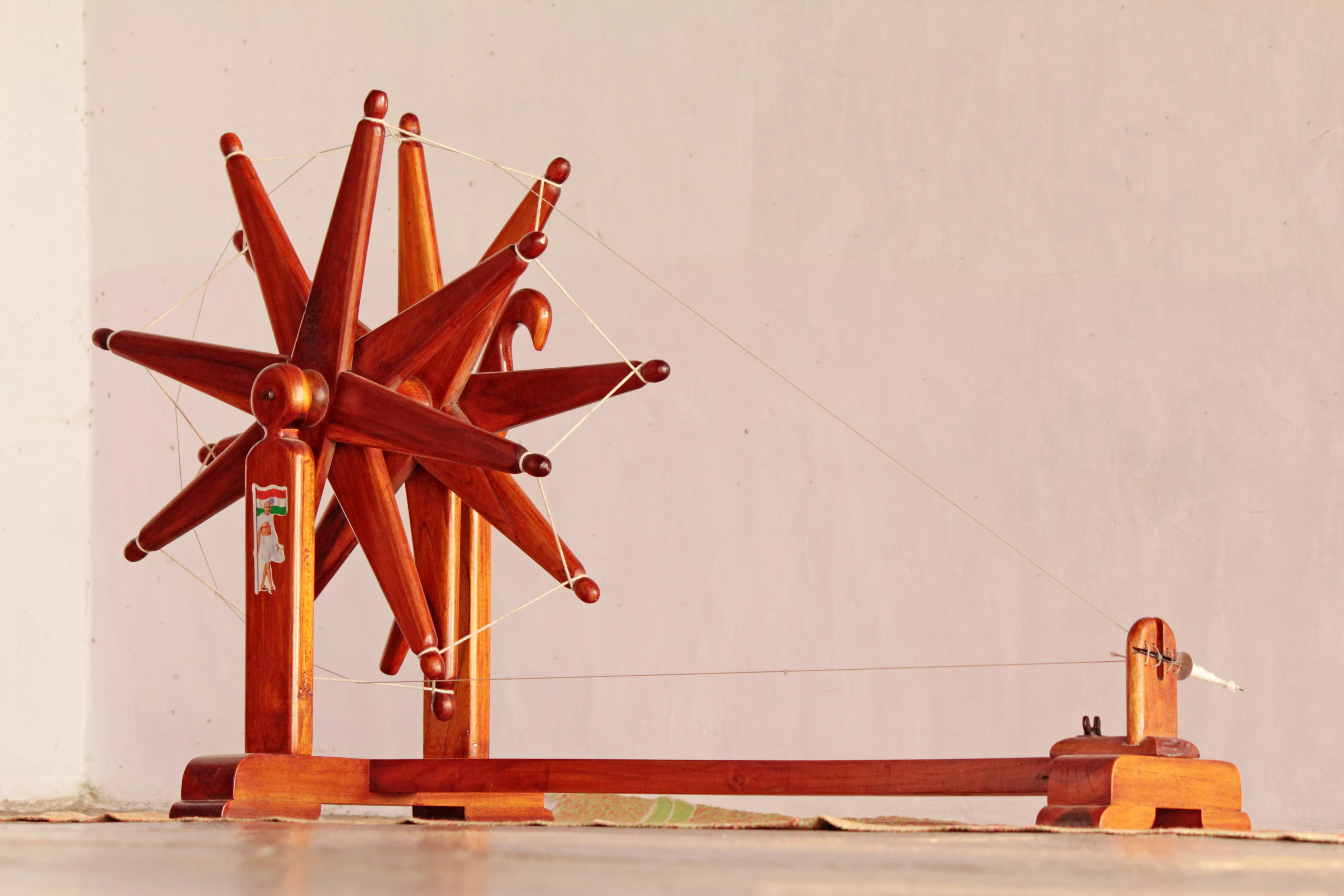

Historically, several major forms developed:

Each variation adapted the same core principle to different fibers and social contexts.

Compared with the drop spindle, the spinning wheel allowed:

This made it possible to supply yarn at a scale sufficient for professional weaving, rather than purely domestic use.

For hundreds of years, spinning wheels defined the upper productivity limit of pre-industrial yarn production.

The spinning wheel represents a decisive conceptual shift:

In technological terms, it is a bridge between hand tools and true machinery.

Finger-twisting

→ Thigh spinning

→ Drop spindle

→ Spinning wheel

→ Spinning Jenny

→ Industrial spinning machines

The spinning wheel is the last major innovation before mechanized mass production.

COMMENTS (0)

Please Login to join the discussion.